Product We will supply good quality products based on trust with customers.

- Product

- Product Introductionn

Product Introductionn

Butt-Welding Pipe Fittings

Butt-Welding Pipe Fittings

Dsigned to be welded on site at its end(s) to connect pipe(s) together and allow change in direction or pipe diameter, or branching or ending.

Widely utilized oil and gas industries, including upstream (exploration and production), midstream (transportation by ships, pipeline, rail, trucks; storage and wholesale)

and downstream (refining into fuels or chemicals; marketing and distribution).

Power plants using fossil or nuclear fuels.

Geothermal energy for harnessing heat from the earth.

KS

Korean Industrial Standards

JIS

Japanese Industrial Standards

ANSI

American National Standards Institute

Grooved Fittings

Grooved Fittings

The most versatile, reliable and economical pipe fitting. It is more reliable than threaded or flanged connection and often results in faster installation. The system is designed to work with rolled or grooved pipes.

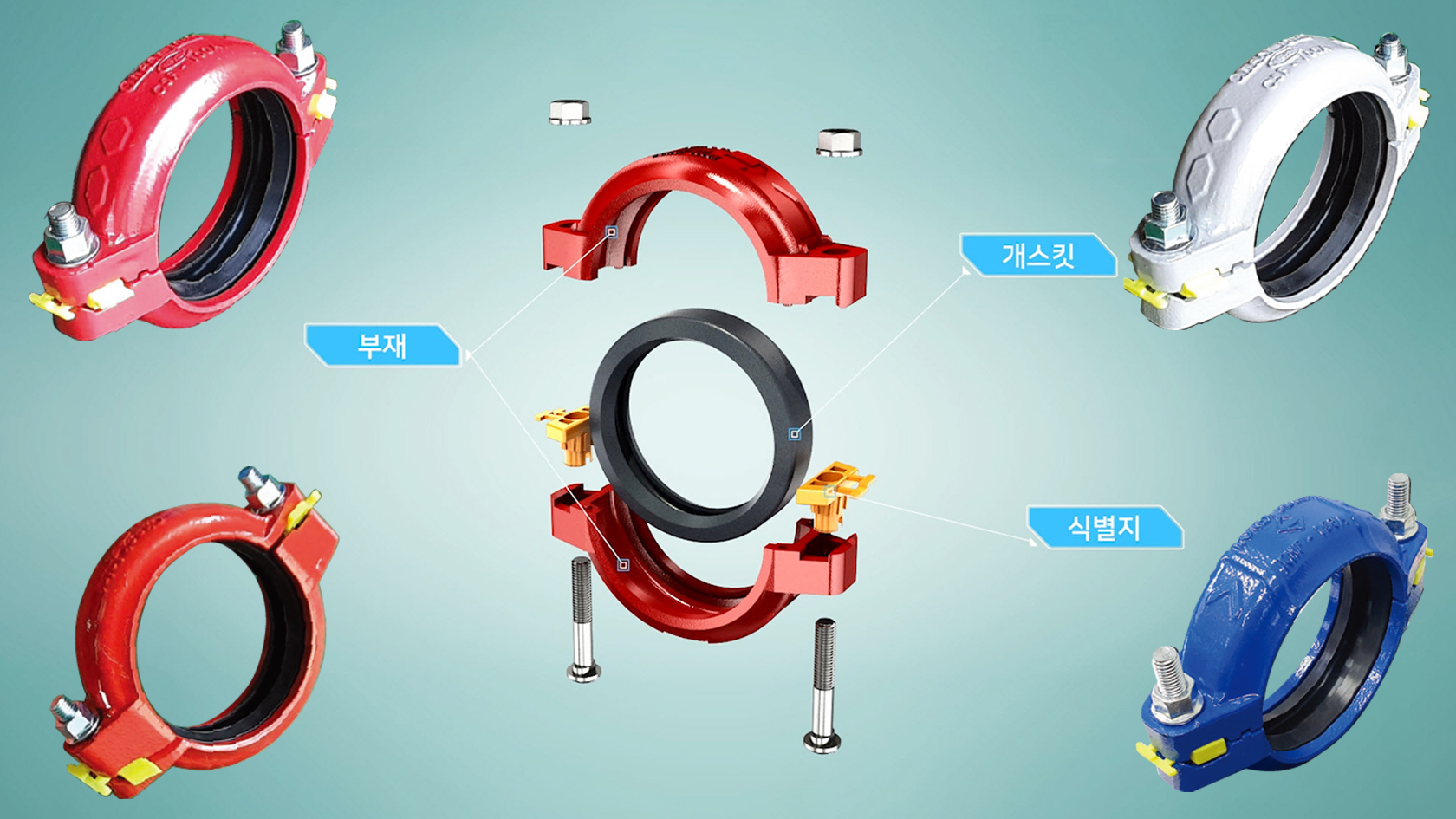

Check Joint

Check Joint

Based on the past 24 years of experience and know-how in the non-welding groove method, a domestic patent was acquired in 2018 (a function that allows confirmation of accurate fastening status by cutting identification paper). Since then, the next-generation Check Joint technology, which has been proven through numerous construction site deliveries, is a product differentiated from existing joints in that it aims for minimum defect rate and perfect construction. It provides clear construction confirmation to workers and supervisors through a device called an identification paper. We provide simple and reliable inspection.